Introduction: India’s Rise as a Global Sourcing Hub

In today’s dynamic global economy, India has emerged as a top sourcing destination for international buyers seeking cost efficiency, quality manufacturing, and sustainable practices. Over the last two decades, India has transformed from a textile-focused exporter into a diversified manufacturing powerhouse spanning automotive, pharmaceuticals, electronics, apparel, and IT services.

With a strategic geographic location, a vast talent pool, and strong government initiatives such as “Make in India” and “Production Linked Incentive (PLI)” schemes, India offers unmatched opportunities for global buyers looking for reliability and scalability.

Historical Perspective: From Textile Traditions to Modern Manufacturing Powerhouse

Early Trade Legacy and Colonial Impact

India’s sourcing story dates back thousands of years, when it was renowned for its fine cotton, silk, and spices that attracted merchants from Europe and the Middle East. The British colonial era further shaped India’s export infrastructure, establishing ports and trade routes that later evolved into global supply chains.

Economic Reforms and Industrial Expansion (1990s–Present)

The 1991 economic liberalization marked a turning point. The dismantling of trade barriers and introduction of FDI-friendly policies encouraged international companies to invest and manufacture in India. Today, India is among the top five global manufacturing destinations, thanks to its liberalized trade policies and economic resilience.

Key Reasons Why Buyers Prefer India for Sourcing

Competitive Pricing and Cost-Effective Production

India’s cost advantage remains one of the biggest draws for global buyers. Labor costs are significantly lower than in Western countries and remain competitive compared to China and Vietnam. Additionally, the presence of SMEs and tiered suppliers enables scalable sourcing at every budget level.

Skilled and English-Proficient Workforce

India boasts a young, educated, and English-speaking workforce that makes communication seamless for international buyers. Technical proficiency across sectors like IT, engineering, and textiles ensures high-quality output and strong project management.

Robust Supply Chain and Logistics Network

Over the past decade, India has invested heavily in improving logistics through the Dedicated Freight Corridor (DFC), Bharatmala projects, and port modernization. These advancements have streamlined export operations, cutting lead times and ensuring consistent delivery performance.

Government Initiatives and Pro-Business Policies

Programs like “Make in India”, PLI schemes, and Ease of Doing Business reforms have attracted massive foreign investment. These initiatives simplify regulations, offer tax incentives, and promote export-oriented industries—making India a pro-investment ecosystem.

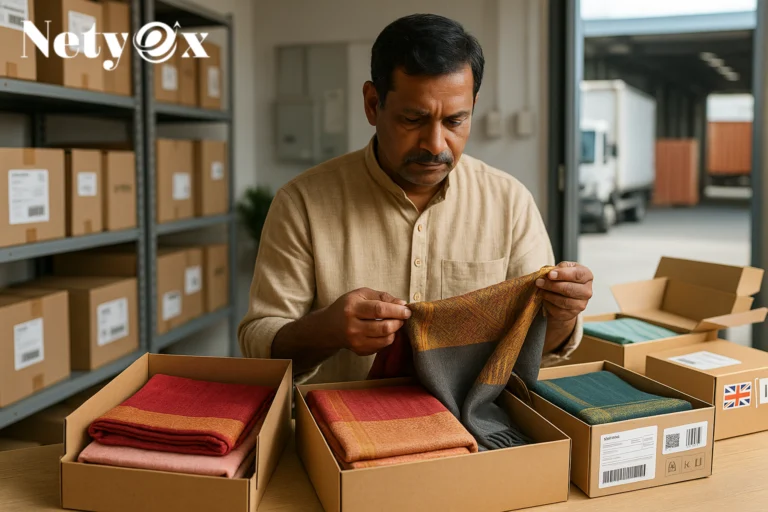

Quality Manufacturing and Global Compliance Standards

Indian manufacturers have made significant strides in meeting international standards like ISO, BSCI, and SA8000. From textiles and leather goods to electronics and pharmaceuticals, India ensures rigorous quality control through modern testing and certification systems.

Diversified Product Range Across Industries

Unlike countries that specialize in only a few sectors, India offers a broad industrial base—from handicrafts and furniture to automotive components and medical devices. This diversification reduces dependency risks for buyers and allows one-stop sourcing across multiple categories.

Innovation, Technology, and Start-up Ecosystem

India’s booming start-up ecosystem and focus on Industry 4.0 technologies such as AI, robotics, and IoT are transforming its manufacturing landscape. Companies leverage these tools for precision, automation, and efficiency, giving India a futuristic edge.

Sustainability and Ethical Manufacturing Practices

Global buyers are increasingly prioritizing sustainability and transparency. India has embraced eco-friendly manufacturing through renewable energy use, water recycling, and ethical labor practices. Many Indian suppliers are now certified by international sustainability standards.

Cultural Compatibility and Strong Buyer-Seller Relationships

India’s business culture emphasizes long-term partnerships and adaptability. Its cultural alignment with Western values—such as transparency, respect, and collaboration—enhances relationship-driven sourcing models that buyers value deeply.

India vs. Other Major Sourcing Destinations

India vs. China: Quality, Flexibility, and Cost Analysis

While China has dominated global sourcing for decades, rising labor costs, trade tensions, and stricter regulations are prompting buyers to look elsewhere. India offers greater flexibility in order sizes, lower production costs, and a democratic, stable business environment, making it an attractive alternative.

India vs. Vietnam, Bangladesh, and Indonesia: Emerging Alternatives

Countries like Vietnam and Bangladesh are emerging players, but they often specialize in limited sectors such as textiles or electronics. India, on the other hand, provides sectoral diversity, skilled manpower, and robust infrastructure, offering buyers a comprehensive solution for varied sourcing needs.

Success Stories: Global Brands Sourcing from India

Major global brands such as Apple, IKEA, H&M, and Toyota have established strong sourcing operations in India. Apple, for instance, is ramping up iPhone production through local partners like Foxconn and Wistron. IKEA sources sustainable furniture from Indian SMEs, demonstrating India’s capacity for quality, scalability, and sustainability.

Challenges and How India is Overcoming Them

Despite progress, challenges such as bureaucratic delays, infrastructure gaps, and complex taxation remain. However, government initiatives like GST simplification, digital customs clearance, and logistics digitization are addressing these hurdles. Continued investment in infrastructure and technology is expected to further boost efficiency.

Future Outlook: India’s Path to Becoming the World’s Top Sourcing Hub by 2030

With its rising manufacturing output, growing exports, and sustainable production, India is on track to become one of the world’s top sourcing hubs by 2030. The government’s focus on self-reliance (Atmanirbhar Bharat), combined with foreign collaboration, will propel India’s manufacturing ecosystem into the global top three.

FAQs About Why Buyers Choose India Over Other Sourcing Countries

Q1. What makes India stand out among global sourcing destinations?

India combines cost-efficiency, quality manufacturing, and a skilled workforce, supported by favorable government policies.

Q2. Which industries are most popular for sourcing from India?

Textiles, automotive parts, pharmaceuticals, furniture, IT services, and handicrafts are among the top sectors.

Q3. How does India compare to China in terms of production costs?

India offers lower labor costs and flexible order quantities, making it highly cost-competitive compared to China.

Q4. Are Indian manufacturers compliant with global quality standards?

Yes, most exporters adhere to international standards such as ISO and BSCI certifications.

Q5. Is communication easy with Indian suppliers?

Absolutely. India’s English proficiency ensures smooth and transparent communication with global buyers.

Q6. What sustainability initiatives exist in Indian manufacturing?

India promotes renewable energy, water-efficient production, and ethical labor practices across industries.

Conclusion: India’s Competitive Edge in Global Trade

In a rapidly shifting global supply landscape, India has positioned itself as a trusted, diverse, and sustainable sourcing destination. With cost advantages, skilled labor, innovation, and strong government support, India’s sourcing potential is unmatched. As global buyers look beyond traditional markets, India stands out as the future of responsible and scalable sourcing.